SAWLINE SCANNERS

Sawing line scanners control the log and cant movements for optimum yield. Depending on the line layout, side boards can be optimised either with a cant scanner (profiling line) or with edger scanners. All scanners have various implementation types depending on the line mechanics. For example log scanner can be built with two scanner heads to fit into a smaller space. All scanners can be built on profile sensors or digital matrix cameras, and line lasers. We will offer the best suitable option for your line structure.

For example log scanner can be built with two scanner heads to fit into smaller space. All scanners can be built on profile sensors or digital matrix cameras, and line lasers. We will offer the best suitable option for your line structure.

Optimisation

Log Scanner ProfiScan™-1GigE

ProfiScan-1 is a log scanner for automatic log rotation. ProfiScan-1 creates a polar coordinate 3D-model of the scanned log and determines the direction and value of sweep. Proper log rotation has proven to have a significant impact on sawing line yield.

Benefits:

- fully automatic

- improved yield

- better quality of sawn timber

Realtime control of automatic log rotation Profi-TC

Profi-TC is a realtime control of log rotation, which is based on texture analysis of log surface. Lisker Oy’s Profi-TC concept installation improves sawing line yield considerably! Profi-TC systems take care of controlling over 10 million cubic of round wood each year with top yield.

Benefits:

- log rotation average error 0, standard deviation below 5 degrees

- yield increase even over 3 %

- eliminates systematic rotation errors automatically

Technical specifications:

- image capture and processing speed approx. 400 images/s

- camera resolution 5 megapixels

- fast response time and high resolution improve rotation accuracy

Cant Scanner

ProfiScan™-2GigE

ProfiScan™-2 is a cant scanner for optimizing sideboards. The system optimizes the positions and widths of sideboards. The customer can set optimization criteria based on, for example, volume or value yield. With two camera/laser pairs, sideboards can be measured and optimized on two sides of the cant. By adding a third camera/laser unit above the cant, boards can also be optimized on the top and bottom surfaces of the cant. Depending on the setup, ProfiScan-2 optimization can achieve an improvement of over 10% in volume yield for sideboards.

Benefits:

- proven yield over 99 %

- fully automatic

- works with high line speeds

Edger Scanner

ProfiScan™-3GTR

ProfiScan™-3 measures the board blank on the longitudinal conveyor after centering, before the edger, and produces a three-dimensional model of the blank. The optimization routine determines the option that provides the best volume yield and sends the corresponding blade control values to the line control logic. The program can also optimize the board at an angle within the maximum allowable skewing limits.

Benefits:

- high yield

- fully automatic

- works with high line speeds

- Two-sided scanning ProfiScan-3:

- sensors on both sides (up & down)

- profile sensor technology

ProfiScan™-1inf

The ProfiScan™-1inf measuring device can be installed as a log scanner at the saw feed to control the rotation of the log’s butt and top, providing guidance on how to rotate the log. Additionally, the device monitors log classification and other log parameters before the log reaches the saw line. Reject commands can be issued for unsuitable logs, allowing them to be removed from the line.

Benefits:

- log turning

- log-dimensional data

- log rejection

Control of dimensional accuracy

ProfiScan™-2GTR

ProfiScan™-2GTR monitors the cant height with fresh measurements immediately after sawing, allowing for immediate response to deviations. With highly accurate measurement technology, it is possible to calculate the success of centering and rotation, as well as measure any sawing steps. Measurement data allows for addressing sawing process issues and correcting them before they result in a drastic decrease in yield.

Benefits:

- control of the dimensional accuracy of cant height

- calculation of successful alignment and rotation

- measurement of sawing offset

ProfiScan™-CTRL

ProfiScan™-CTRL measures the thickness of board and plank blanks, immediately identifying sawing deviations after sawing. The informative user interface provides the sawyer with real-time information on the success of the sawing. The compact measuring device can be installed in the first or second phase of sawing without major mechanical modifications.

Benefits:

- measures the thickness of the piece along its entire length

- dimensional accuracy 0.1 to 0.2 mm

- provides real-time feedback about the quality of the sawing

- informative user interface

- easy to install without great mechanical changes

AUTOMATIC GRADING

Automatic grading of sawn timber, both fresh and dry, is commonplace for sawmills. Lisker Oy offers products for lines operating with or without a turner. “Lite” versions are also available for both options, which only grade the faces of the sawn timber.

In our experience, starting from a production of 30,000 cubic meters, investment in automatic grading is profitable. The latest camera technology, the use of line lasers for identifying all shape defects, and efficient program algorithms ensure a fast and optimal result.

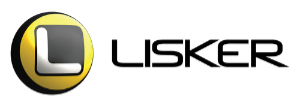

Automatic grading with piece turner, ProfiGrade™ TFE-6

ProfiGrade™ TFE-6 has been “the workhorse” of automatic grading already for 20 years for small and large mills, for green and dry grading. Systems grade annually millions of cubic of sawn timber. Components chosen have proven their reliability in industrial, harsh environments. We aim to provide cutting-edge solutions for our customers so that they can prosper. We work every year on R&D projects to enhance our products even further.

Benefits:

- industry tested technology

- excellent in detecting deformations and colour defects

- certified for strength grading (complementary and visual)

- can be modified to ProfiGrade 360 (without piece turner)

Automatic grading without piece turner, ProfiGrade™ 360

The ProfiGrade™ 360 concept has been developed for lines where sawn timber pieces are graded without turning the piece. We have concentrated on R&D to introduce a concept where keeping the components clean and functional below the line is easy. Scanning below the line is carried out in one position, and components are properly covered against dust. We have also kept in mind the possibility of upgrading existing ProfiGrade TFE-6 system to the ProfiGrade 360 model – and it can be done! ProfiGrade 360 mechanics are simple to construct and easy to maintain.

The ProfiGrade™ 360 concept supports simple and effective conveyor solutions, which in turn improve the level of grading and facilitate mechanical maintenance.

Benefits:

- scanning below the line in one position

- components below are well covered against dust

- simple mechanical structure

- compact, fits into smaller space

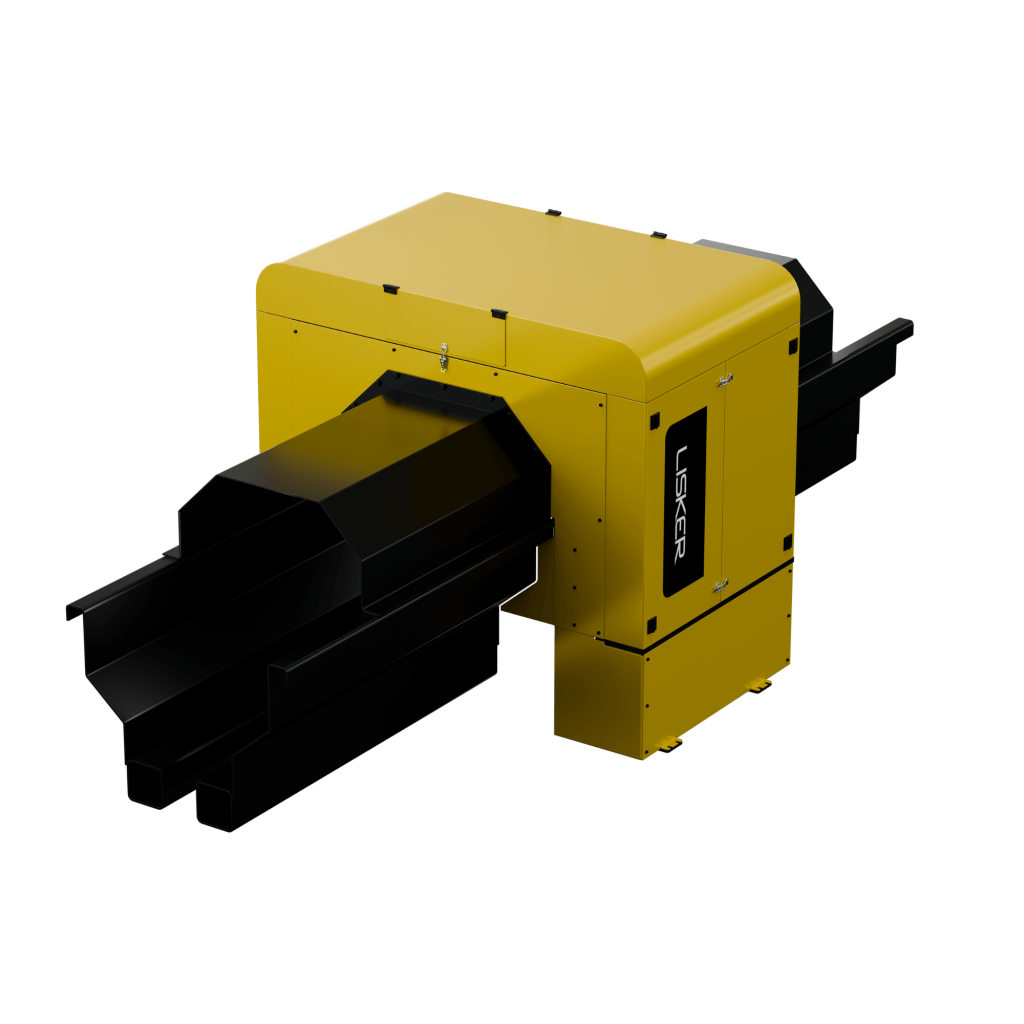

Board end scanner, Profi-BE

Lisker has developed the Profi-BE measuring equipment for measuring the end of a piece of lumber. The Profi-BE measuring device can operate as a standalone system or it can be connected to the ProfiGrade grading system, allowing ProfiGrade to intelligently utilize the measurement data produced by Profi-BE to support grading algorithms, and to sort pieces based on the measured quantities.

Measurable quantities:

- position of pith

- growth ring width

- inner-outer piece separation in 4xlog

- inner-outer face recognition

PRODUCTION MANAGEMENT AND CONTROL

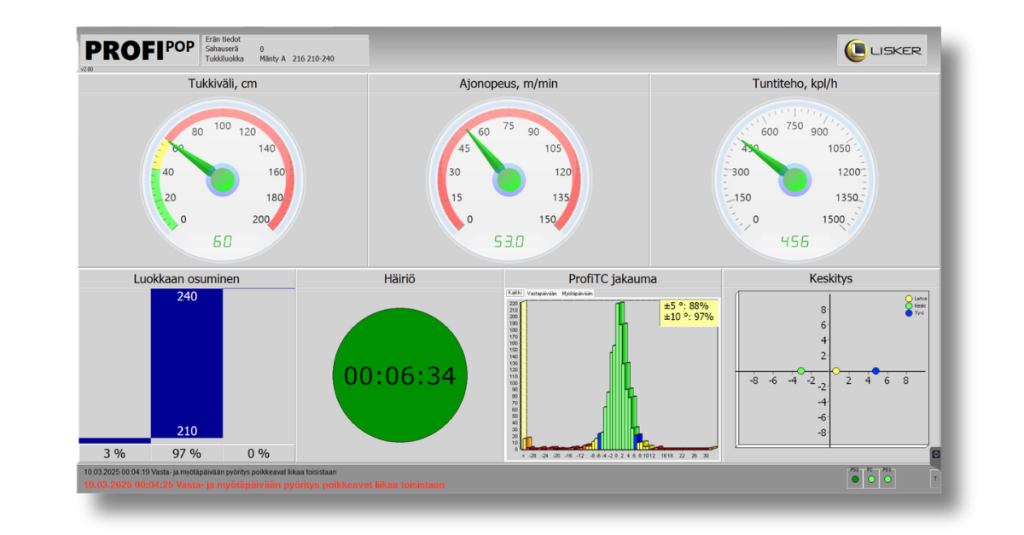

ProfiPop

The ProfiPop power display provides the operator with real-time information about the different stages of the cutting process, helping to keep the saw line performance at top level.

Benefits:

All essential output and accuracy indicators of the saw line at a glance: log spacing, drive speed, hourly output, category fit, failures, alignment success, and rotation distribution.

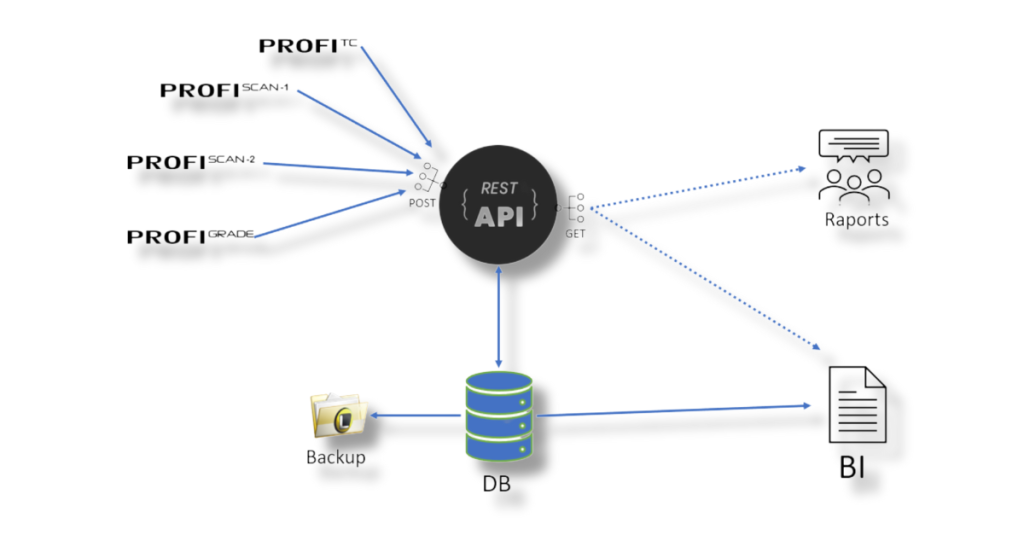

ProfiApi

ProfiApi combines all Lisker Profi series measurement devices into a single whole. Data collection makes it possible to gain deep insights into the performance of the saw line and to analyse the process. Reporting provides valuable information about the process and can generate customer-specific reports for all needs.

The data can be imported into the customer’s own reporting or BI system via the modern connection interfaces. The Lite version of the system gives customers access to all data, allowing them to retrieve the data into their own systems without long-term storage.

Benefits:

- scales with the volume of and need for data

- can be connected to all Lisker-measurement devices

- modern connection interfaces

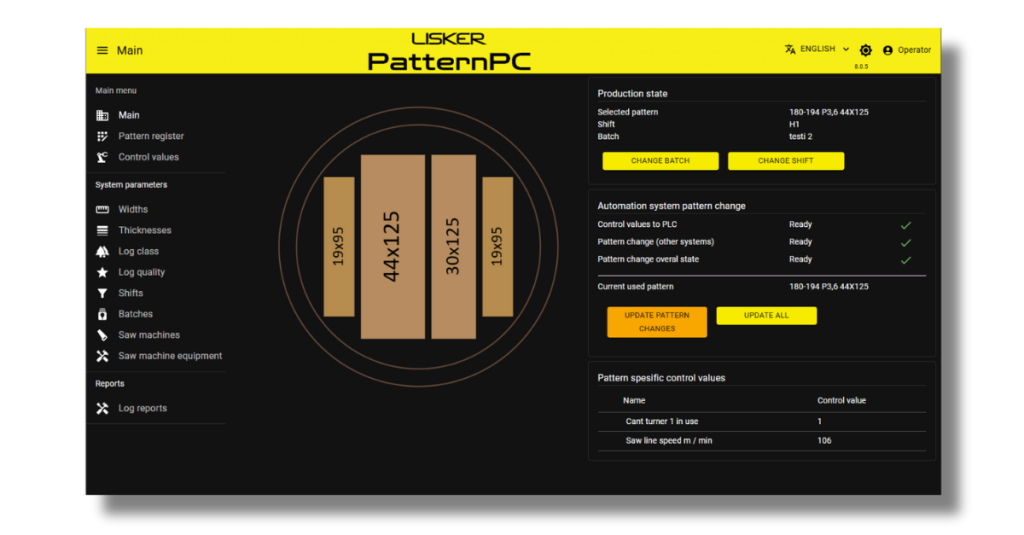

PatternPC

PatternPC is a tool for designing sawing dimensions and controlling the sawing machine. The system includes a versatile web-based user interface for the management and switching of dimension settings. The positions of all actuators involved in the sawing are calculated on the basis of the activated dimension setting and conveyed to the automated control system. Setting change progress can be viewed in the intuitive user interface. In the visual dimension setting view, the positions of the actuators can be checked and timber piece-specific corrections can be made, which affect all required actuators symmetrically.

Benefits:

- clear web-based user interface

- illustrative piece dimension adjustment functions

- connections with automated systems