Better yield for the sawline

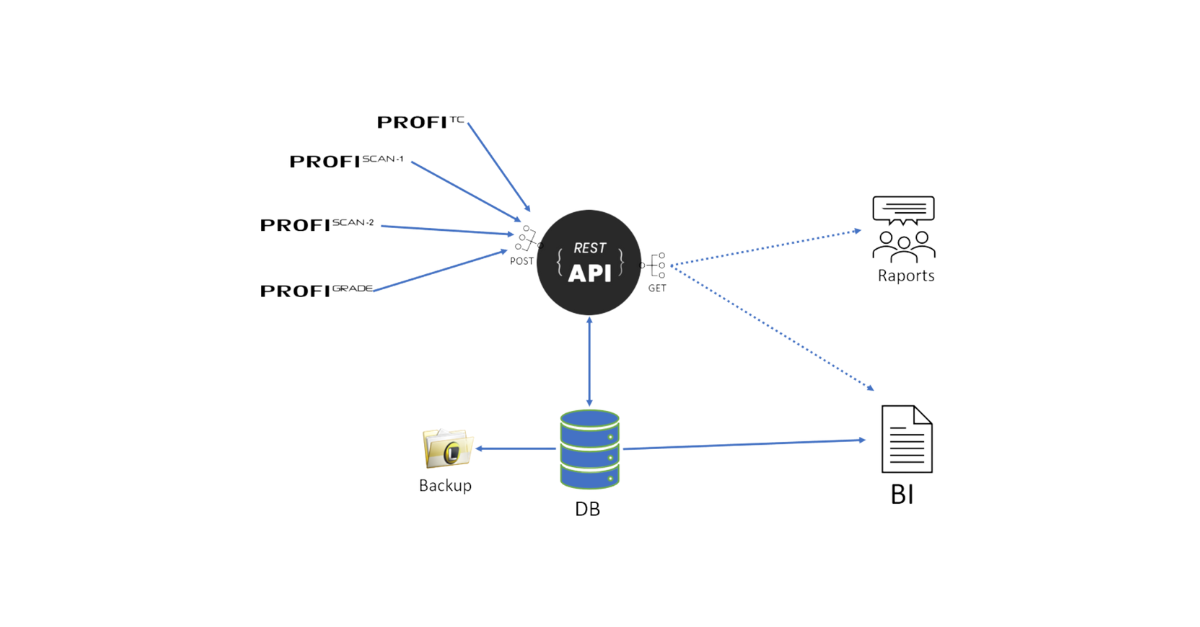

Solutions covering feeding, sawing, measuring, and grading.

NEW

ProfiGrade™ AI

Lisker has released a new ProfiGrade AI update, which brings AI-assisted timber defect detection as part of the familiar ProfiGrade grading system.

We are a Finnish Automation Company Founded in 1987

Lisker is an automation company founded in 1987, specializing in measurement and optimization systems for sawmills. Our extensive product portfolio covers scanners from sawmill feeding and log measurement to dry lumber grading.

With raw material costs being the most significant expense for sawmills, we specialize in systems that improve sawmill yield and profitability. Some products have a payback period of just a few months! We also conduct ‘before and after’ tests to concretely demonstrate the benefits achieved for the customer.

Lisker Oy has delivered over 350 measurement and optimization systems to 16 countries for various sawlines. Our measurement and optimization programs are 100% our own production, allowing them to scale according to customer needs.

Optimization Philosophy

Wood is an organic material whose quality is influenced by its growth environment, soil, weather conditions, biological environment, initial processing during harvesting, and many other factors. Therefore, each piece processed at the sawmill is unique.

The goal of sawmills is to utilize every purchased cubic meter of logs as efficiently as possible and with the highest possible yield. Lisker’s measurement and optimization systems recognize the properties of the wood and make decisions that can increase the sawmill’s yield.

350+

systems delivered worldwide

10M+

cubic meters of logs are measured annually with our equipment

40+

years of experience in the sawmill industry

100%

Finnish design and programming

Products

Our company specializes in the production of automatic measurement and optimization systems for the wood industry. The core of our operations is to improve the yield, efficiency, and thereby the profitability of our clients’ facilities.

Clients

Our systems are in use in Finland, the Nordic countries, and many European countries.

News

ProfiGrade AI – The Next Level of Grading

Lisker has released a new ProfiGrade™ AI update, integrating AI-assisted timber defect detection into the established ProfiGrade grading system.

Read morePredictive Maintenance as Part of Sawmill Optimization

Maintaining the sawline is not just about mechanical upkeep, but also about continuously ensuring measurement accuracy. Predictive maintenance helps keep production smooth and yield high.

Read moreDNA chain of logs improves identification on the sawmill line

The new algorithmic application developed by Lisker can identify logs with up to 95% accuracy on the sawmill line, bringing transparency, cost benefits, and certainty to the process for sawmills.

Read moreIntelligence on the Saw Line Is Based in Software

Sawmill industry systems need to stay up to date, adapt to changes, and continue working even when the technology around them changes. Software is never finished – but it still needs to last for decades.

Read moreMachine Vision Is Not Enough, if the System Cannot Understand Wood

CTO Panu Toukola explains how practical sawmill conditions, the long lifecycle of software, and machine vision form the basis for smart measurement and optimisation solutions.

Read moreLog Rotation Optimization – Tens of Millions in Added Value for the Sawmill Industry

“When discussing millions of euros in additional revenue from just more precise rotation, sawmills cannot afford to overlook this.”

Read more